What is direct drive technology?

What is direct drive technology?

With direct drive technology a torque motor is coupled directly to the driven load. This provides a very stiff mechanical connection to the load, eliminating problems associated with couplings, belts and gearboxes.

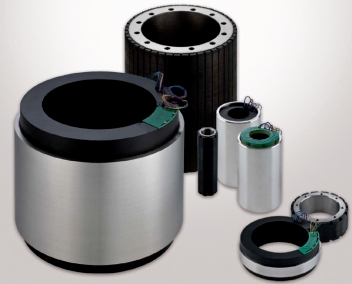

Kollmorgen KBM

KBM™ Series frameless kit brushless motors are designed to be embedded in your machine. The rotor is supported by machine's own bearings.

A large selection of standard motors are available or alternatively a bespoke solution incorporating your specific modifications can quickly and cost-effectively create a an exact fit motor which will provide the highest performance and longest life in the most compact space.

Designs, which include special winding configurations, tailored mounting features, diameter and stack length dimensional adjustments, or material variations, are all possible.

Simplified Machine Design.

With a Kollmorgen KBM Solution from Micromech, your machine design is simplified. Noisy mechanical transmissions are eliminated as are the performance limitations associated them.

The direct coupling of a torque motor to a load provides improvements to a machine, unachievable with a more compliant mechanical transmission. Furthermore, expensive maintenance is greatly reduced as the need to adjust belts or pulleys or to lubricate gearboxes is eliminated.

Direct drive frameless vs Conventional Motor Systems

Conventional servo systems with mechanical transmissions limit servo performance and reliability. Typically designs consume more space due to use of transmissions, belt / pulley arrangements and couplings. Additionally maintenance is more extensive. This all adds unnecessary machine down time and costs.

Integration Costs

Life Cycle Costs

Micromech engineers have assisted many of our customers with specification of a KBM frameless motor solution. Contact us for further information on the wide variety of pre-engineered options and configurations available or send us your exact requirements for a custom solution for your application. Call 01376 333333 or Email sales@micromech.co.uk