Mon 12th Aug 2024 - Micromech is excited to announce the addition of SPINEA TwinSpin® High Precision Compact Gearheads to our range of motion control products

Established 1994 in Slovakia, SPINEA is a technology leader in the manufacturer of high precision compact gearheads. SPINEA gearheads were initially designed for the robotic industry and are used in robots such as KUKA and ABB but soon began to supply other markets including moulding machinery, food and beverage manufacturing, machine tool, security and surveillance, medical and construction robotics.

SPINEA has worldwide presence with local offices in Germany and China and numerous sales partners all over the world.

SPINEA has strong research and development capabilities and has patents on numerous products.

SPINEA’s state of the art engineering capabilities enable joint product development with customers as well as tailored solutions to suit any application.

The TwinSpin® range:

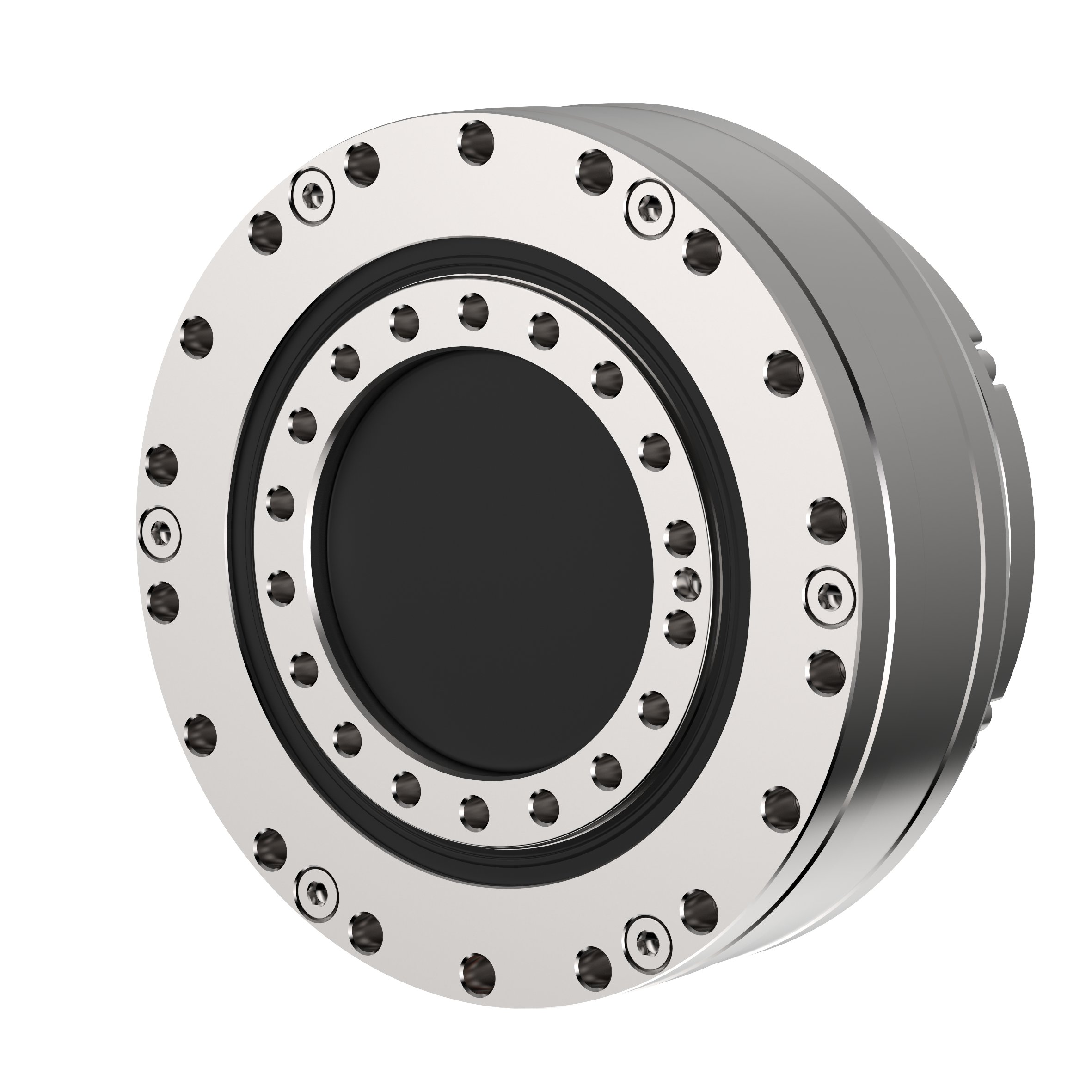

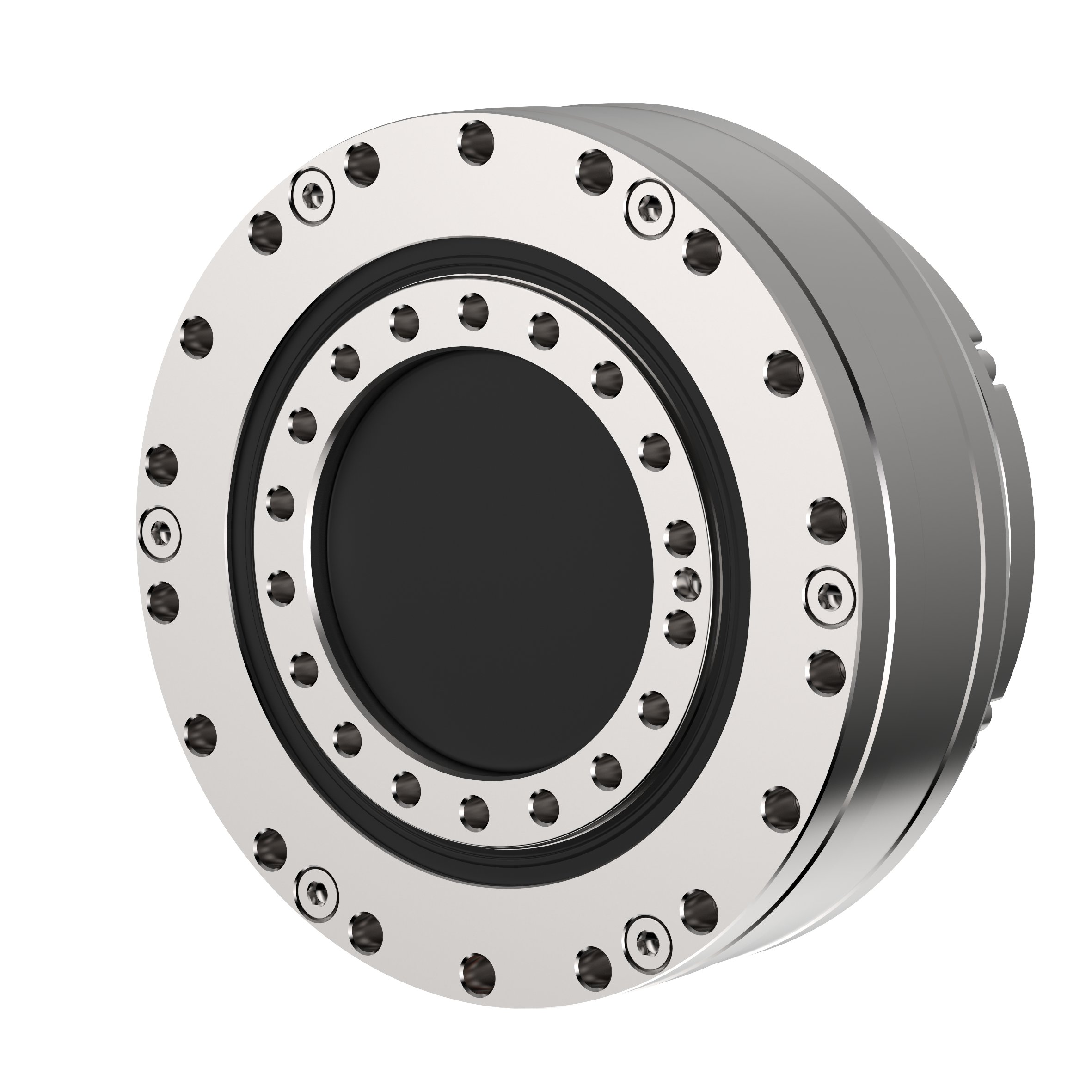

T Series

The T series is a range of high precision reduction gearheads with a cylindrical case comprising an accurate reduction mechanism and high-capacity radial and axial cylindrical roller bearings.

This design allows the mounting of the load directly on the output flange or the case without the need of additional bearings.

Custom motor flanges are available.

Advantages

- Zero backlash reduction gears

- High moment capacity

- Excellent positioning accuracy and positioning repeatability

- High torsional and tilting stiffness

- Compact size

- High reduction ratios

- Long lifetime

- Easy assembly

E Series

The E Series is a wide range of high precision reduction gearheads with all of the benefits and advantages of the T series in a flange shaped case

H Series

The H Series also has the same accurate mechanism and benefits of the T and E series but features a hollow-shaft. Cables, tubes for compressed air, drive shafts etc. are able to be passed through the shaft.

Advantages

- Large input shaft diameter

- Hollow shaft

- Fully sealed

- Zero backlash reduction gears

- High moment capacity

G Series

G Series

The G series is a new generation of TwinSpin® high precision reduction gearhead with a new design main bearing and improved performance for the most demanding applications.

G series has an increased in torque to weight ratio when compared to the previous generation.

Innovative design of main bearing resulted in the unprecedented tilting stiffness, high precision of the output bearing, and modularity of design which allows for customized solutions. Other improvements include further friction reduction in the transmission mechanism, lower hysteresis and low settings of Lost Motion, especially in small sizes.

The G Series is also available in a Hollow shaft version.

GH Series

Advantages

- high tilting stiffness

- Low friction

- High precision output bearing

- High torque density

- Reduced lost motion settings

- High torque overload capacity

M Series

The M Series is a miniature range of high precision reduction gearheads.

The M series is lubricated for life. The design of the reduction gears allows the load to be mounted directly on the output flange or the case without the need for additional bearings.

Advantages

- Small dimensions and compact design

- Fully sealed by 2RS ball bearings

- Simple installation

- Zero-backlash reduction gear

- Very low mass

- Very high power density

- High precision

- High torsion rigidity

- Very low friction and high efficiency

As a SPINEA sales partner our applications engineers are fully trained to specify and support SPINEA gearheads. Please call if you have an application you think may be suitable for a SPINEA high precision gearhead.

Disclaimer

The use of this news article and images came with permission from SPINEA.

The T series is a range of high precision reduction gearheads with a cylindrical case comprising an accurate reduction mechanism and high-capacity radial and axial cylindrical roller bearings.

The T series is a range of high precision reduction gearheads with a cylindrical case comprising an accurate reduction mechanism and high-capacity radial and axial cylindrical roller bearings.

G Series

G Series